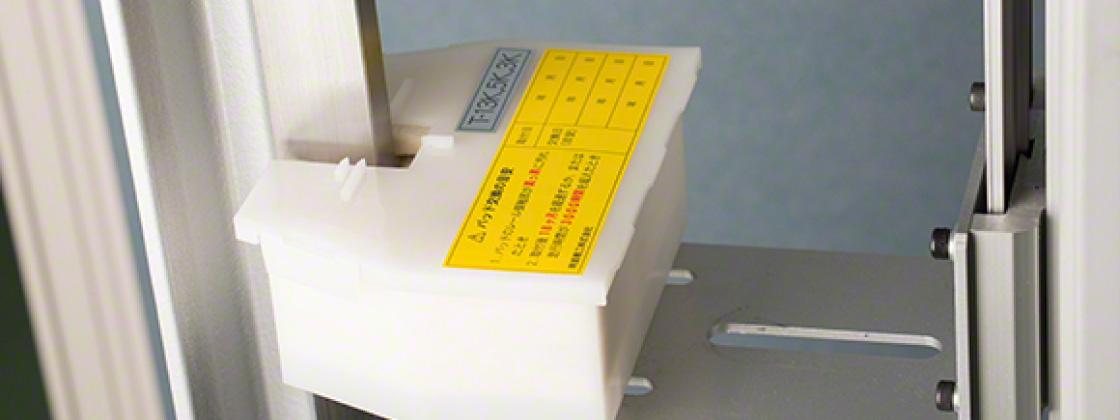

Elevator Guide Rail Oiler Flat Oiler (Long life)

Features

■ Direct

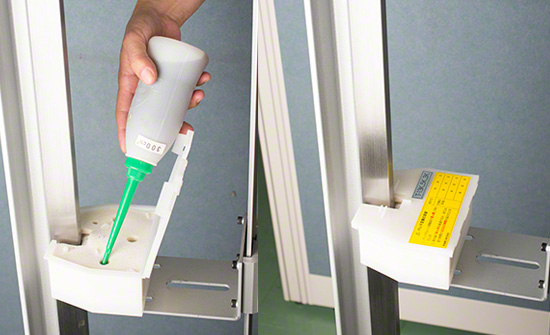

- Oil is applied to the rail surface, maintaining the oil film at the necessary and most minimum amount. (300㎤ oil will last for more than a year.)

- Extra strong new material has been adopted in the friction part of oil retaining material; therefore, a product life of 2 years or more is achieved.

- Oil adjustment is not necessary.

■ Indirect

- The need to ride on top of the elevator cage for oiling has reduced greatly. Therefore, carrying heavy oil cans to the spot and wiping contamination oil is no longer necessary. This leads to the shortening of maintenance time and reduction of personnel organization.

- The height of the case has been downsized to less than 1/3 the size of the conventional one. It is ideal for "elevators without machinery space" which have only limited space on top of the elevator cage.

- It is suitable for “observation elevator” since there are no worries of oil scattering.

- Remarkable effect is achieved especially in elevators in cold regions, since it is not influenced by viscosity change of the oil and the characteristic are always maintained constant.

- The conventional oiler which required frequent oil supply hindered the introduction of "remote monitoring system". However, with this installation, the problem can be solved.

■ Variation

| Applied Rail |

8K Rail | 13K Rail | 18K Rail / 24K Rail |

30K Rail |

|---|---|---|---|---|

| Oiler Type |

T-8K | T-13K | T-18K, T-24K |

T-30K |

General Drawing

Product Information page